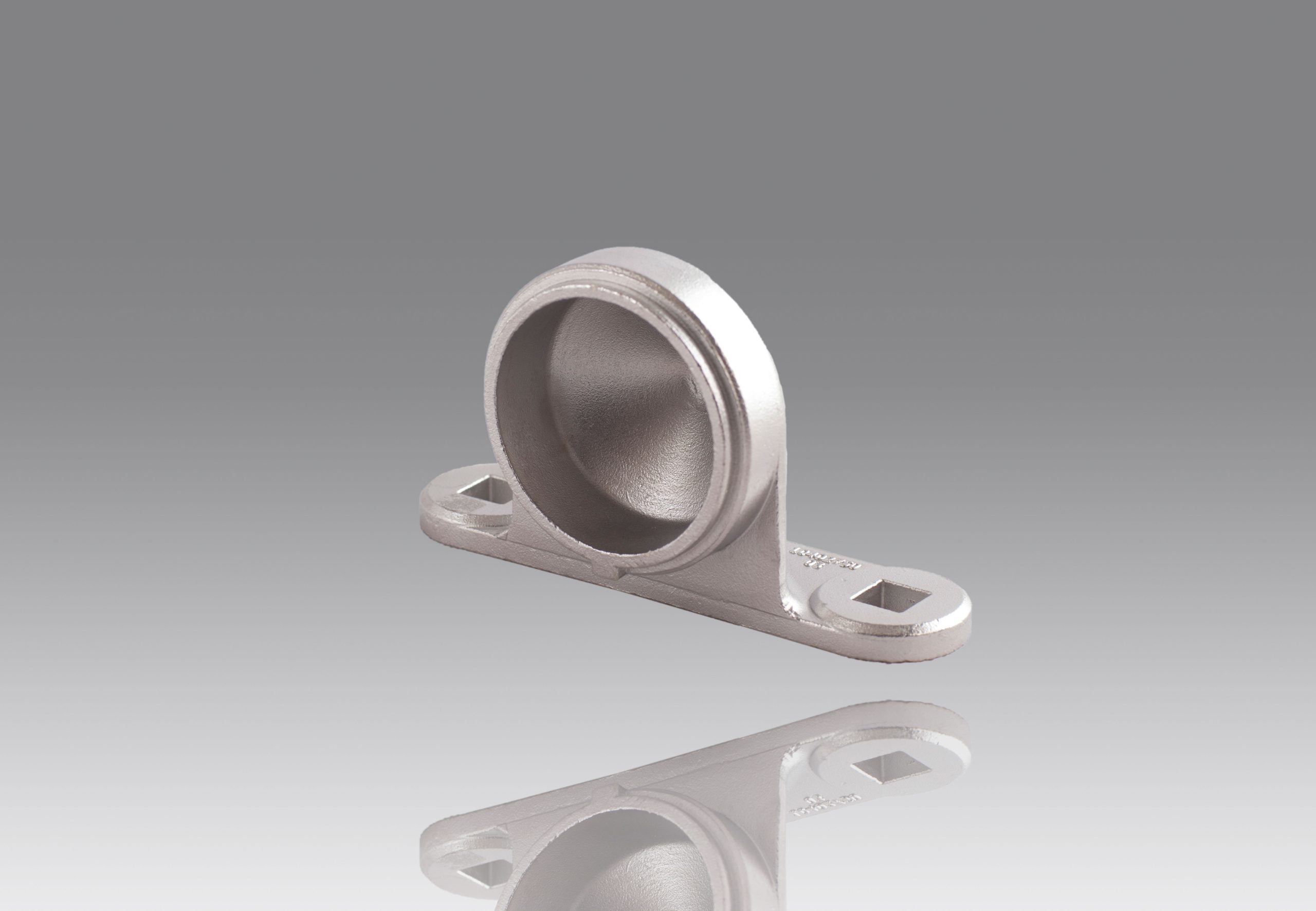

At Alumess, we provide a comprehensive range of steel casting and metalworking technologies. For steel and stainless steel casting, we specialize in lost wax casting and sandcasting. Using the Silica Sol casting method, we achieve high precision casting for complex parts, while the water glass casting method is ideal for larger steel components.

Alumess has been a trusted partner for the food industry, particularly in the production of stainless steel parts and stainless steel components. In addition to casting, we offer manufacturing design, prototyping, finishing, and full assembly services, ensuring a complete and seamless production process.

Our expertise in lost wax casting allows us to create intricate stainless steel and steel parts with exceptional detail and accuracy.

When it comes to larger steel castings, our sandcasting process delivers durable and reliable results, perfect for industrial applications.

Using the Silica Sol casting technique, we offer high precision casting solutions for industries that demand extreme accuracy in stainless steel and steel parts.

For larger steel components, the water glass casting method provides a cost-effective and efficient solution, ensuring strength and durability in every part.

Alumess offers end-to-end solutions for steel casting, including design, prototyping, and assembly, ensuring the highest quality from start to finish.

For additional details about our aluminium extrusion technologies or to discuss your project, feel free to contact us.

contact us